A few examples of current and exploratory developments:

Even though much of the work is performed in a consulting capacity, occasionally needed custom equipment is developed and built to support the verification and validation work. Some of this equipment / tools are shown here.

Point machine simulators

Used for real-time simulation of actual physical AC point machines during design and validation testing. Allow changing of operational parameters such as timing via WLAN during testing scenarios while simultaneously monitoring and logging driving circuitry behaviour.

Please see two stacked point’s simulators below. Note each simulator contains protection circuitry against over-heating (simulation of actual motor coils).

Signal head simulator

The simulator allows simulation of LED signal head faults and failures for 8 circuits during design and validation. Allow changing of operational parameters such as fault /failure level during testing scenarios, while simultaneously monitoring and logging the driving circuitry behaviour (voltages, currents).

Please see the signal head simulator below. Note: all voltages and currents are monitored

for each circuit. Additionally the current selected status is indicated by the LEDs (in this case all aspect indications off).

Safety diagnosed AC mains driven LED Signal head:

Exploratory development of an LED based signal head with the required safety monitoring of functional integrity.

The AC mains current to the signal head is monitored (on the left) together with the signal head integrity.

The AC signal is rectified to DC and drives the LED array (middle). It also contains the LED array monitoring circuitry.

The actual LED head simulation is shown on the right together with switches allowing control of fault and failure conditions.

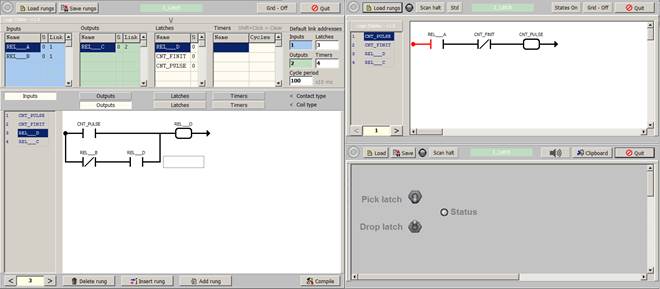

PC based logic implementation with hardware interface:

A graphically configurable logic engine running on a standard Windows PC; linked via USB to external input/output circuitry.

This environment can be employed as a PC based programmable logic controller (PLC) or as a teaching aid to teach signalling principles based on specific ladder logic implementations (very common in the railway sector).

The logic development and run-time environment consists of a number of applications, which allow both development of the ladder logic as well as white box display of the running logic together with a graphical user interface containing such elements as switches, etc.

Previous systems developed and actively used on actual projects:

In the past, complete simulated environments have been assembled in hardware and software allowing comfortable testing of safety systems covering both manual as well as automated testing (based on a test catalogue allowing easy regression testing).

Depending on the customers’ needs and expectations, any conceivable test environment can be developed and constructed. The cost, time to develop and functionality of such systems is fully negotiable and at the discretion of the customer.